Remote Valve Actuation

Mechanical remote valve actuation systems are a straightforward solution to simplify your installation process and decrease maintenance costs.

Our Products

Remote valve actuation is the process of controlling a valve’s operation at a safe or convenient distance, eliminating the need for manual intervention at its physical location. Most mechanical remote valve actuation is done using mechanical, electrical, pneumatic or hydraulic actuation systems.

Elliott’s mechanical actuation systems are the only stand-alone, self-contained remote valve actuation methods that operate without supplemental energy sources or additional components. Mechanical remote valve actuation systems are commonly found in industrial, naval shipbuilding, government defense, nuclear applications and AI data centers. These systems are used as primary operational and redundant safety systems, as well as fail-safe operational systems to reduce exposure to hazardous conditions. They are a straightforward option to ensure operators have a back-up solution to manually shut down equipment.

Key advantages of remote valve actuation systems

Without the need for an external electric power source, mechanical remote valve actuation systems decrease design issues, safety concerns and the need for frequent operational inspections. Opting for a mechanical actuation system also means a less complicated installation process and fewer maintenance costs.

Elliott offers and supports two mechanical remote valve operation product lines:

- Standard valve control

- Uniflex

Standard valve control

Two types of standard valve control systems are available, and they are defined by the primary drive mechanism: rigid rod or flexible shaft. The systems are equal in quality and approved for many applications, including naval shipbuilding, conforming to Naval Sea Systems Command (NAVSEA) specifications. Within this application, Elliott also offers the option for nuclear product capability, with specialized components like shielded wall penetration and floor-housing assemblies, complete with indicators, mounting and handwheels.

These systems are made up of round carbon or stainless-steel bar, gearboxes, swivel gear joints and universal joints to route around obstacles or change routing direction. Rigid rod systems are ideal when the path of a remote valve operating system is straight or nearly straight.

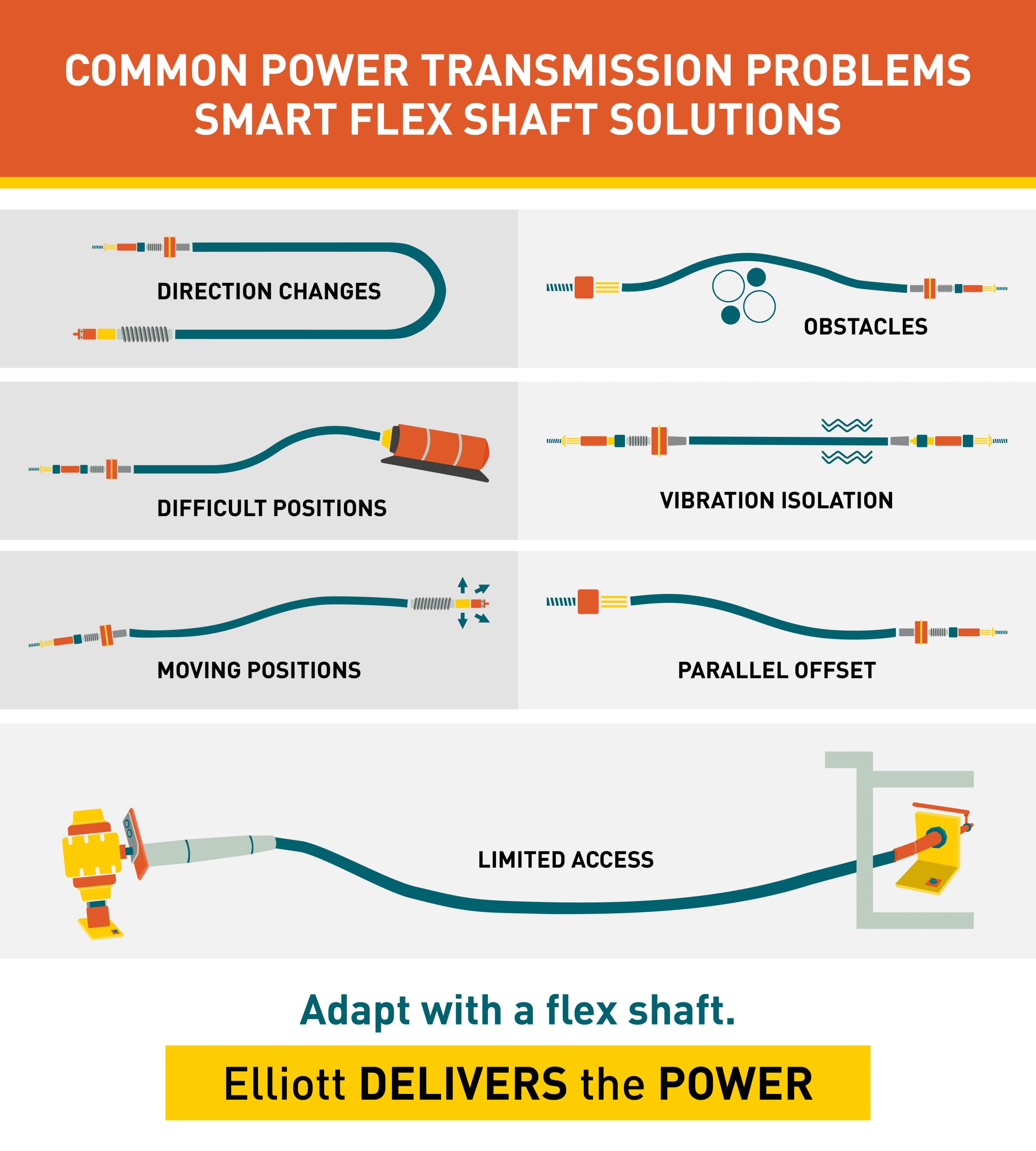

A flexible shaft can be used in place of a gearbox, universal joint or rigid rod system. Flexible shaft assemblies are extremely durable, and installation is more forgiving than a rigid rod system. They can easily be installed around obstructions or through passageways and mounted to any rigid structure. Flexible shafts also can be fitted with a range of handwheel sizes to suit the required input torque, using most of the same components as a rigid rod system. Flex shafts are available in steel with a galvanized casing or stainless steel with a phosphor bronze casing.

Elliott also manufactures numerous adaptors and other fittings so a combination of rigid rod and flexible shaft systems can be used together to handle particularly challenging design problems.

Uniflex Valve Control

The Uniflex remote valve operation system is commonly used in the military, marine, commercial shipping, power generation and offshore industries, and designed with components and fixtures that withstand intense shock, vibration and salt spray. Components are manufactured using high-grade bronze, brass and stainless-steel materials while meeting shock and vibration specs, including MIL-SW-901C Class 1 and MIL-STD-167-1 Type 1.

Uniflex is a geared system using a combination of torque reduction at the input point and torque multiplier or increaser (valve station actuator) at the output point to minimize load on the flexible shaft and reduce the amount of torsional deflection. This design allows the valve station actuator to withstand shock loads exceeding 500% of its ratings and provide exceptional performance, reliability and long life in most environments, as opposed to a standard gearbox that uses involuted tooth gears with limited contact points.

Market Examples

With our unique, robust design, Elliott flex shafts and control cables address the special conditions that occur in military operations, like extreme temperature ranges, chemicals, moisture, salt spray, intense torque load and continuous operation at high speeds.

A comprehensive solution for remote operation of valves, Elliott systems mean no exposed moving parts, valves that can operate virtually anywhere, a minimum number of moving components and a simplified installation process.

Remote valve actuation systems offer reliable control from a distance, making it easy to operate valves in high and low locations, under water or in tight and confined spaces, all from a secure and accessible position.

For precision performance in demanding conditions, choose Elliott remote valve actuation systems for flex shafts that transmit rotary power over, under and around obstacles and provide intense torque load and continuous operation at high speeds even in hazardous conditions.

Remote valve actuation systems can play an essential role in regulating, isolating and controlling fluids and gases within a data center. Elliott systems are rugged and flexible, and control is precise and responsive. From chilled water loops and fuel systems to fire suppression, air handling and wastewater treatment, remote valve operation ensures safe and efficient operations.

Contact Elliott

Interested in more information about our remote valve actuation products? Elliott’s customer service team is here to support you. Please contact us for assistance.