Flexible Shaft

Product Highlights

- Tested & Proven Reliability

- Highly Dependable Solutions

- Made in the USA

- Built-in Quality

- World Class Customer Service

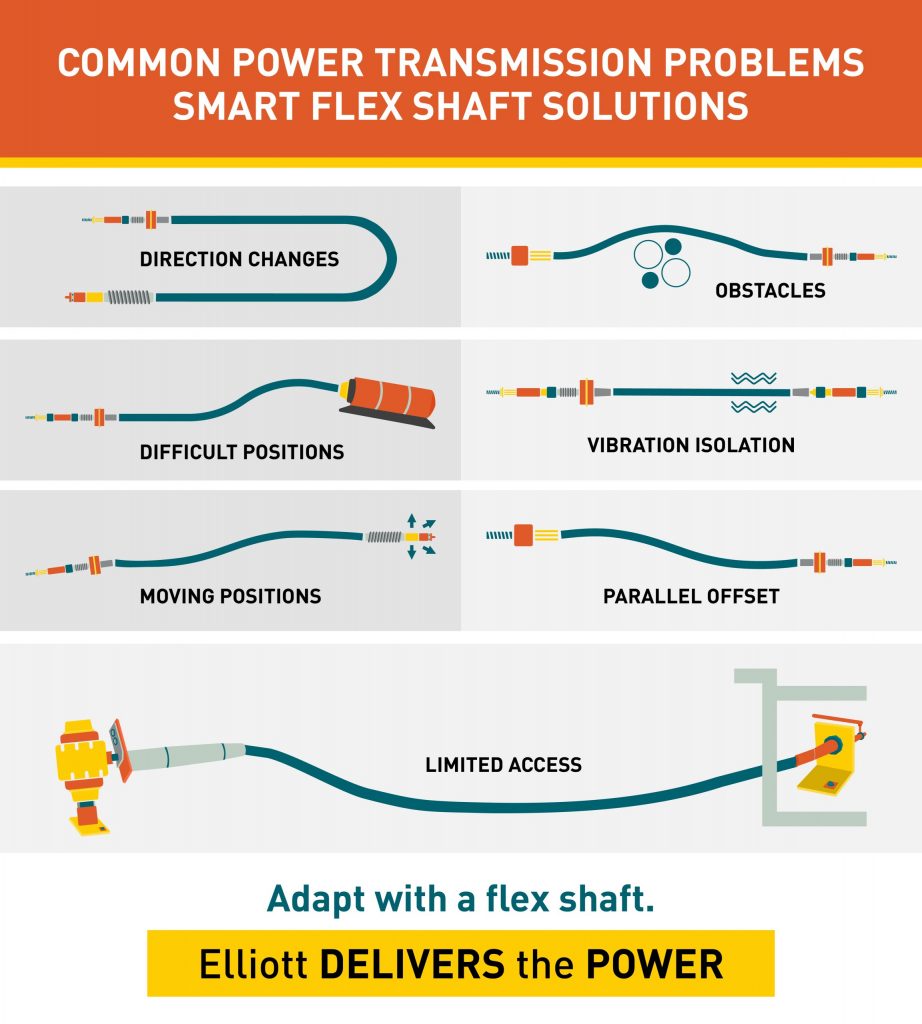

Elliott Flexible Shafts are designed to transmit power or rotary motion through a curved path, either between fixed shafts or shafts having relative motion.

They can overcome problems of misalignment, absorb and isolate vibration, and simplify power transmission designs and applications. Elliott Flexible Shafts can easily withstand the shock of sudden load changes due to starting and stopping. They will effectively and reliably transmit power to a driven element that must move during operation, even around corners or into machines while allowing for a high degree of freedom in the location of drive sources, whether mechanical, such as electric motors or manual.

Using Flexible Shafts to solve complex drive problems can reduce design time, lower initial assembly and maintenance cost safely without the use of exposed universal joints, gears, pulleys or couplings. Consider Elliott Flexible Shafting early in your design to take full advantage of this unique technology to solve demanding drive problems efficiently, economically and with the flexibility you need.

FAQ

A flex shaft is a complete mechanism capable of transmitting rotary power or motion between two points that need not be co-linear. Flex shafts are available in a wide range of configurations and materials to meet your needs. Flex shafts are very durable and can operate in demanding environments, even if continuous operation at very high speed is required. There are two primary types of flex shafts:

- Power drive: Designed for continuous operation at speeds exceeding 100 RPM where torque is carried in one direction of rotation. It may also be used where intermittent operation is an application requirement.

- Remote control: Designed for intermittent operation at speeds of 100 RPM or less. Remote Control Flex Shafts generally handle higher torque loads than Power Drive Flex Shafts and can rotate either clockwise or counterclockwise without adverse effects.

Generally, a flex shaft is made up of the following:

- Core: Wire wound in layers in opposing directions around a center wire.

- Casing: Flexible conduit that supports the core during operation. Many of Elliott’s flex shafts come with a casing comprised of a steel liner, steel and cloth reinforcing braids and an elastomer cover.

- Motor connection: This is what attaches the flex shaft to a power source. There are many different motor connections ranging from the simple single fitting to a more complex multi-faceted system.

- Fitting: A core fitting is attached directly to the core to mate to the power source.

- Ferrule: A ferrule attaches to the casing to support it in a uniform bend and to keep it from rotating.

Some systems will have each of these components while others may only have a few.

We can help you determine if the torque, speed and environment of your application are appropriate for a flex shaft. Visit our Markets pages to learn more about how our products are used.

Our Core Specifications is a good place to start. You should know the power you need to transmit, operating speed, direction of rotation, minimum bend radius and torsional deflection. We can figure it out for you if you need help.