Agriculture Products

Long history of providing industry leading Agricultural products...

-

2003

Elliott began production of Agricultural Seeders for John Deere

-

2013

Production of Agricultural Seeders for CNH and AGCO began

-

2016

Launch of RowControl and SurfaceDrive products for the Agricultural Aftermarket

Award-winning technology available to you today. Upgrade your existing planting system this Season in less time than it takes to get the chains and sprockets ready to go. It’s as easy as 1-2-3.

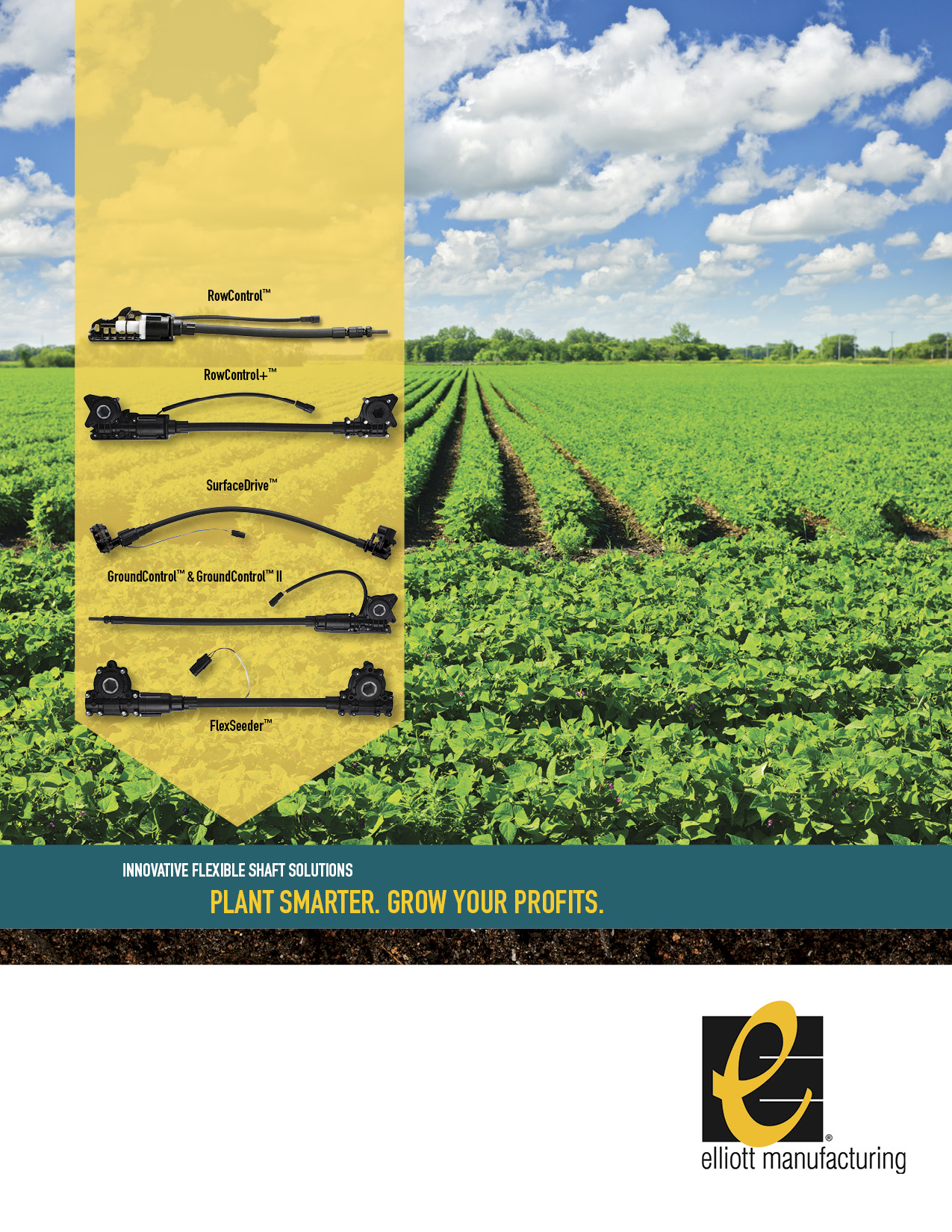

Elliott Flexible Shaft Drive Systems

Elliott’s flexible shafts are asked to perform in a variety of applications. Whether it’s precision performance, demanding conditions or high-operational reliability, Agriculture requires it all.

Flexible planting products extend mechanical advantages without the need for additional power sources. If your planter has a toolbar, you already have all the power you need to drive any one of our precision planting products.

For more information on our innovative flexible shaft drive systems for planters, check out our catalog. Since 2003, we have produced more than 2 million flexible drive assemblies to fit most planters on the market today, including John Deere, AGCO, Kinze and Case IH.

Plant Smarter. Grow Your Profits.

- RowControl™ and RowControl+™ Drive Systems: Add an inline clutch to your John Deere planter with a Pro-Shaft™ drive. RowControl+ allows you upgrade your chain and sprocket planting system, with or without a clutch.

- SurfaceDrive™ Drive System: Attach to your existing Precision Planting vSet® seed meter for on/off row control with Elliott’s proprietary clutch.

- GroundControl™ Drive System: Keep your investment up and running with our compatible row control replacement for John Deere Row Command™ products.

- GroundControl™ II Drive System: Direct plug-and-play drop in for John Deere ProSeries™ row units using RowCommand. Benefit from your equipment investment for years to come

- FlexSeeder™ Drive System: Replace your chain and sprocket system on John Deere and Kinze planters with a maintenance-free flexible shaft drive system. Our widest ranging product made for a variety of planter makes and models.

rowcontrol

If you have a John Deere planter with Pro-Shaft drives and want to add an inline clutch, it’s time you knew about RowControl, Elliott’s easy to install solution for individual on/off row control.

Product Highlights

- Adds individual on/off row control to your current system.

- Substantial seed savings versus overplanting.

- Interfaces with standard planter control software.

surfacedrive

If you’re using Precision Planting’s vSet seed meter, you should see SurfaceDrive, Elliott’s mechanical drive that uses the power from your own toolbar to drive the meter.

Product Highlights

- The mechanical alternative to an electric drive.

- Uses the power of the toolbar to drive the meter.

- Saves money and power draw with results on par with electric drives.

groundcontrol

Just because John Deere no longer offers spare parts for its RowCommand™ product doesn’t mean you can’t continue to benefit from your investment. Elliott’s GroundControl system is a better, fully compatible row control replacement for Pro-Shaft drive planters.

Product Highlights

- Non-indexing clutch offers better and faster control of seed meter

- Reinforced knob with durable aluminum interface and self-locking screws lasts longer

- Easy to install, allowing you to get working quickly

groundcontrol ii

Our new GroundControl II system is a better, fully compatible, row control replacement for all Pro-Shaft driven row units, including the Pro-Series™ XP and MaxEmerge™ XP planters. Plus, Elliott’s innovative design locates the clutch inside the seed meter gearbox, so you can use your existing flexible shafts for fast, easy installation.

Product Highlights

- Option for manual or John Deere Section Control clutch engagement to pause seed distribution

- Reinforced knob with durable aluminum interface and self-locking screws

stands up to harsh environments for maximum performance and life - Easy to install for quick changeover

flexseeder

If your planter is running with chains and sprockets, it’s time for you to learn about FlexSeeder, Elliott’s modular offering for a wide range of planter models.

Product Highlights

- Our widest ranging product made for a variety of planter makes and models.

- Maintenance-free

- Closed system is better suited for No-Till Farming

Technology

- Allows for more accurate seed spacing by reducing backlash in the system

- Lube for life; no maintenance

- 12 volt; low current draw

- Reverse logic technology – clutch drives with no power

- Lube for life; no maintenance

- 2-pin weather pac connector

- No externally rotating parts – designed for today’s no-till environments

- IP66 compliant – fully pressure-washable system

Helpful Links

FAQ

Elliott Manufacturing designed and built the first prototype system in 1998. John Deere began testing and evaluation in early 1999. Elliott then began work with CNH and AGCO OEM drive systems in 2011 and production began in 2013. Since 2013 we have outfitted approximately 1.2 million row units worldwide.

About 4 hours, but watch our installation video for step-by-step instructions and more information.

Elliott has partnered with a number of different companies. Locate your nearest distributor HERE.

Our Engineers have designed FlexSeeder to fit a variety of makes and models. Click here to view the Compatibility Matrix

The ROI is real, and generally recognized in the first year.

It is a complete mechanism capable of transmitting rotary power or motion between two points that need not be co-linear. They are available in a wide range of configurations and materials to meet your needs. Flex Shafts are very durable and can operate in demanding environments, some requiring continuous operation at very high speed. There are two primary types of Flex Shafts:

Power Drive: Designed for continuous operation at speeds exceeding 100 RPM where torque is carries in one direction of rotation. It may also be used where intermittent operation is an application requirement.

Remote Control: Designed for intermittent operation at speeds of 100 RPM or less. Remote Control Flex Shafts generally carry handle higher torque than Power Drive Flex Shafts and can rotate either clockwise or counterclockwise without adverse effects.

Contact one of our application engineers to determine if the torque, speed, and environment of your application are appropriate for Flexible Shafting. Over the past 140 years, Elliott has designed Flex Shafts for literally THOUSANDS of applications ranging from military to commercial to power plants and beyond.

“With the FlexSeeder System, it saved me seed, it had more yield and it saved me headaches I would have by overplanting.”

– Jerry H., Serinville, NE (Video Testimonial)