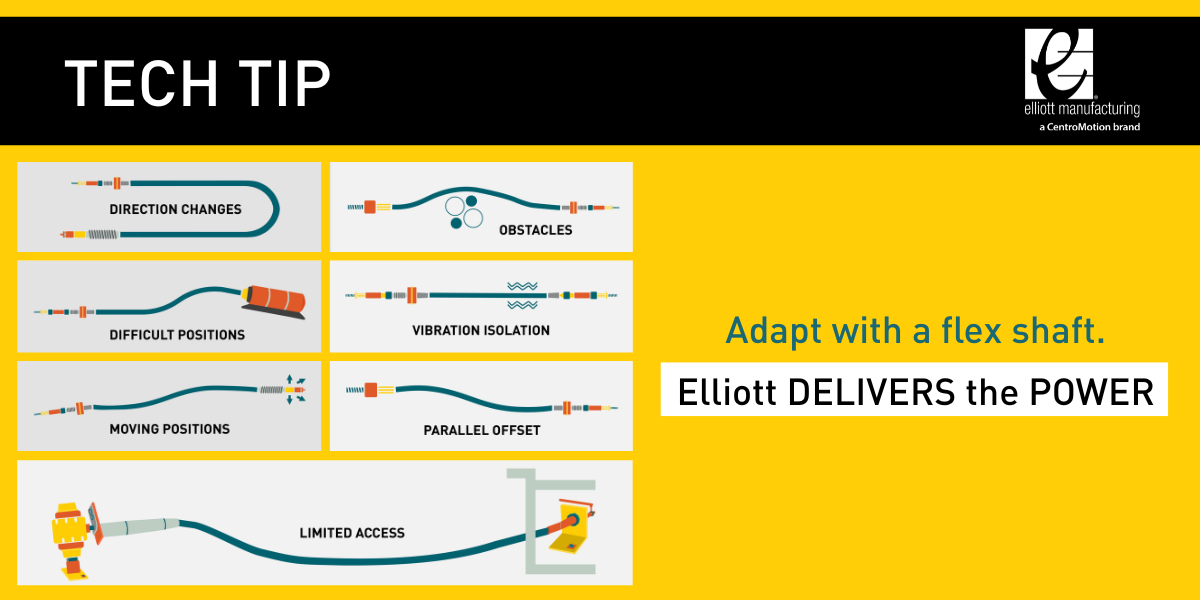

Tech Tip: What kind of barriers can a flex shaft overcome?

A flex shaft is a complete mechanism capable of transmitting rotary power or motion between two points that aren’t in a straight line. Flex shafts are available in a wide range of configurations and materials, are very durable and can operate in demanding environments, even if continuous operation at a very high speed is required.

If your application has power transmission challenges, look at the type of design issues flex shafts can solve:

- Obstacles: Transmit power around obstacles that block a direct path to the final driven end. If multiple obstacles exist, a flex shaft is ideal to bypass these hurdles and actuate the end valve or other driven component.

- Direction changes: Deliver power in opposing directions, at right or left turns and 180 degrees in relation to the overall diameter and length of the flex shaft.

- Vibration isolation: Transmit torque to or from vibrating components to a stable component without transmitting the vibration.

- Difficult positions: Designs that include multiple angles are easily managed because flex shafts ensure a wide variety of mounting and assembly options.

- Moving positions: If the driven end is subject to movement, use a flex shaft to transmit continuous power and ensure ongoing operation.

- Parallel offset: Direct in-line mounting not an option? Transmit power from opposing parallel lines with a flex shaft.

- Limited access: In an enclosed or isolated location, a valve or end device can be easily manipulated from a safe distance because an operator or motor can transmit torque with a flex shaft through barriers like panels, bulkheads, firewalls or containment chamber walls.

Our engineering team can help you determine if the torque, speed and environment of your application is appropriate for a flex shaft.

No matter the industry, whatever the challenge, Elliott can deliver the power. We’ll help you turn the corner and make the connection. Visit our markets page to learn more about flex shaft applications.

What can you adapt with a flex shaft?

See the versatility of our power transmission technology for yourself. Contact us to learn more about our core material. Our sales and product management teams can answer your specific questions.