Our Flexible Shafts Are Shaking Up the Concrete Industry

When concrete is poured, it can contain hundreds, or even thousands, of air bubbles that must be dispersed to ensure a smooth and strong finish after the formwork is removed. Concrete vibrators are used to vigorously shake the freshly poured concrete to eliminate these pockets of air. Concrete vibrator OEMs worldwide look to Elliott Manufacturing flexible shafts to safely and efficiently transmit vibratory power in their products from the power supply to the steel vibrator head.

About concrete vibrators

Flexible shafts are used in immersion vibrators, which are the most common in the industry. They can range in size from small battery-powered wands to large plug-in or gasoline engine powered equipment that can be used for very deep pours. Whatever the application size, a versatile and durable Elliott flexible shaft ensures the vibrator can be easily and correctly positioned into the concrete.

Elliott flexible shafts in action

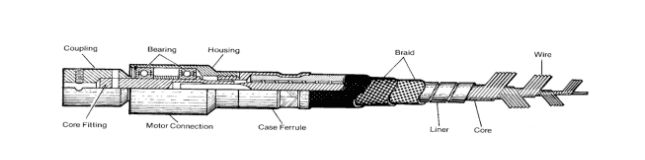

When used in portable construction tools such as concrete vibrators, Elliott flexible shafts replace a motor-in-head vibrator or a pneumatic vibrator. Typically, these flexible shafts have a median core diameter of 0.250”-0.625” with a carbon steel core. The core, which rotates within the casing, is constructed using multiple layers of helically wound wires. The stationary casing performs multiple functions. It:

- protects the core from the environment

- supports the core

- prevents helixing under load

Elliott flexible shaft assemblies can also contain other components, including:

- ferrules (terminals) which are attached to the ends of the casing

- fittings to connect the driving and driven elements

- couplings on each end of the assembly to engage with the mating components

Elliott engineers can work with you to customize any and all of these components to provide the optimal flexible shaft for your tool.

Benefits of Elliott flexible shafts

With an Elliott flexible shaft assembly in your equipment, you’re assured a safe and efficient transfer of rotary power with a range of real benefits including:

- Simple solution when direct alignment is not possible or an issue

- Enhanced vibration absorption and isolation

- Simplified power transmission designs and applications

- Reduction in overall design time

- Lower initial assembly and maintenance costs without impacting safety

- Reduced need for universal joints, gears, pulleys and couplings

About the U.S. ready-mixed concrete industry

Ready-mixed concrete is a widely-used and vital component in the transportation, building sector, residential and other construction markets. Estimates say there are about 5,500 ready-mixed concrete plants across the country and about 55,000 ready-mixed concrete mixer trucks that deliver it to the point of placement. In the U.S., the ready-mixed concrete industry is valued at $35 billion.

What can we design for you?

Elliott Manufacturing engineers can work with to design a flexible shaft system that fits your concrete vibrator or other portable construction tool. Contact us now.